Water quality plays a crucial role in every industrial process. Many industries require high-purity, mineral-free water for efficient operation—and this is where a Demineralized Water (DM) Plant becomes essential.

DM plants remove dissolved solids (TDS), minerals, salts, and impurities from water to produce ultra-pure water suitable for boilers, pharmaceuticals, electronics, food processing, and more.

What is Demineralized Water (DM Water)?

Demineralized water—also known as deionized water (DI water)—is water that has had all dissolved minerals and ions removed, such as:

-

Calcium

-

Magnesium

-

Chlorides

-

Sulphates

-

Nitrates

-

Silica

It is produced using ion exchange technology, making it far purer than filtered or softened water.

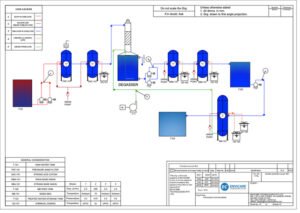

How Does a Demineralized Water (DM) Plant Work?

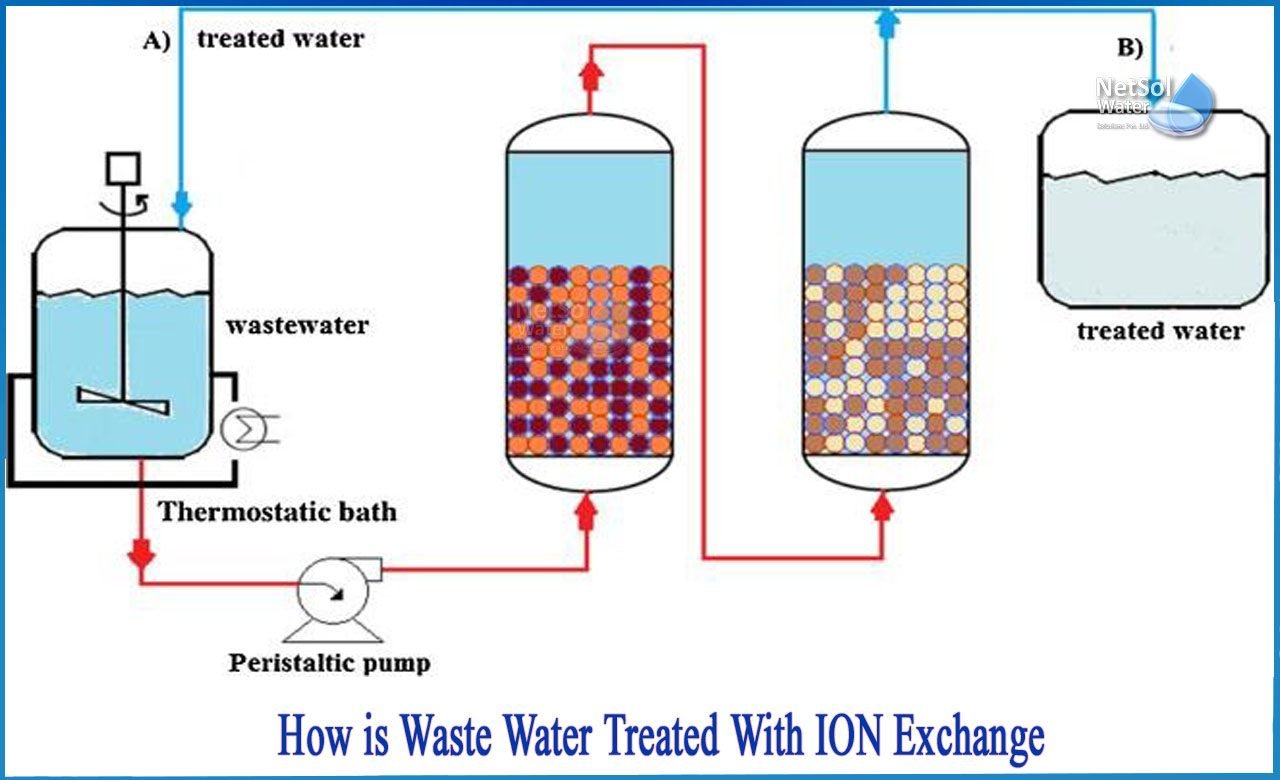

A typical DM Plant uses Cation and Anion Exchange Resin Units to remove dissolved impurities.

1. Cation Exchange Unit

Raw water passes through a cation resin bed, replacing positive ions (Ca²⁺, Mg²⁺, Na⁺) with H⁺ (Hydrogen) ions.

2. Anion Exchange Unit

The water then enters an anion resin bed, replacing negative ions (Cl⁻, SO₄²⁻, NO₃⁻) with OH⁻ (Hydroxide) ions.

3. Mixed Bed Polisher (Optional)

For ultra-high purity, both resins are mixed together to polish the water, producing extremely low conductivity DM water.

4. Regeneration

Resins are regenerated using chemicals:

-

Cation resin: regenerated with acid

-

Anion resin: regenerated with caustic soda

Benefits of Demineralized Water (DM Water)

1. Mineral-Free High Purity Water

Removes 95–99% dissolved minerals, ensuring consistent quality.

2. Protects Industrial Equipment

Prevents scaling, corrosion, and deposits in boilers, turbines, pipelines, and heat exchangers.

3. Improves Product Quality

Essential for pharmaceuticals, electronics, chemicals, and food industries.

4. Cost Savings

Lower maintenance, reduced downtime, and higher equipment efficiency.

5. Suitable for Multiple Industries

DM water is required anywhere high-purity water is essential.

Industrial Applications of DM Water

DM water plays a vital role in:

DM water plays a vital role in:

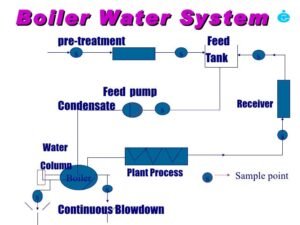

1. Power Plants & Boilers

Used as boiler feedwater to prevent deposits and scaling.

2. Pharmaceutical & Healthcare

Ensures purity in drug manufacturing and laboratory use.

3. Electronics & Semiconductor Industry

Required for wafer cleaning, chip production, and circuit washing.

4. Chemical & Petrochemical Plants

Used as process water and in chemical reactions.

5. Food & Beverage Industry

Ensures high-quality production and cleaning processes.

6. Cosmetics & Personal Care

Used in lotions, shampoos, and cosmetics where water purity matters.

Types of Demineralized Water (DM) Plants

1. Two-Bed DM Plant

Has separate Cation and Anion units.

2. Mixed Bed DM Plant

Provides higher purity—ideal for sensitive industries.

3. Automatic DM Plant

PLC/SCADA-controlled, low manpower, higher consistency.

4. Manual / Semi-Automatic DM Plant

Cost-effective option for small to medium industries.

Why Industries Prefer CFAU DM Water Plants

⭐High-Purity Output (Very Low TDS)

Ensures consistent water quality.

⭐ Automatic & Efficient Operation

Minimal manpower, maximum reliability.

⭐ Durable SS Construction

Corrosion-resistant and suitable for heavy-duty use.

⭐ Custom Capacities: 100 LPH to 100,000 LPH

Designed as per industry requirement.

⭐ 80% Water Recovery Rate

Cost-effective and sustainable.

⭐ PAN India Installation & Support

Free technical assistance and video consultation.

Conclusion

A Demineralized Water (DM) Plant is essential for industries requiring ultra-pure, mineral-free water. Its ability to protect equipment, enhance product quality, and reduce operational cost makes it a smart investment for any modern industry.

As a leading DM Water Plant Manufacturer in India, Complete Filtration & Utility (CFAU) delivers high-performance, durable, and customized DM systems for all applications.

For more details: Call us +91 98792 03051 OR email: info@completefiltrationutility.com